HollowBlockWithTubesAndHotwell

Created Tuesday 08 April 2014

This model defines the basic geometric parameters of a hollow block with tubes and a hotwell.

1. Purpose of Model

The model is used to define the geometry of a block-shaped control volume (of the level of detail L2/L3) with a tube bundle in it for heat transfer and a hotwell for accumulating condensate.

2. Physical Insight

The volume and heat transfer areas are calculated according to the properties shown in the next list:

- Diameter of the tubes

- Length of the tubes (one pass)

- Number of tubes in parallel

- Number of passes of the internal tubes

- Block Dimensions (Length, Height, Width)

- Orientation of the block (direction of the flow through it)

- Hotwell dimensions (Length, Height, Width)

3. Limits of Validity

Lengths and diameters of the passes should be greater than zero.

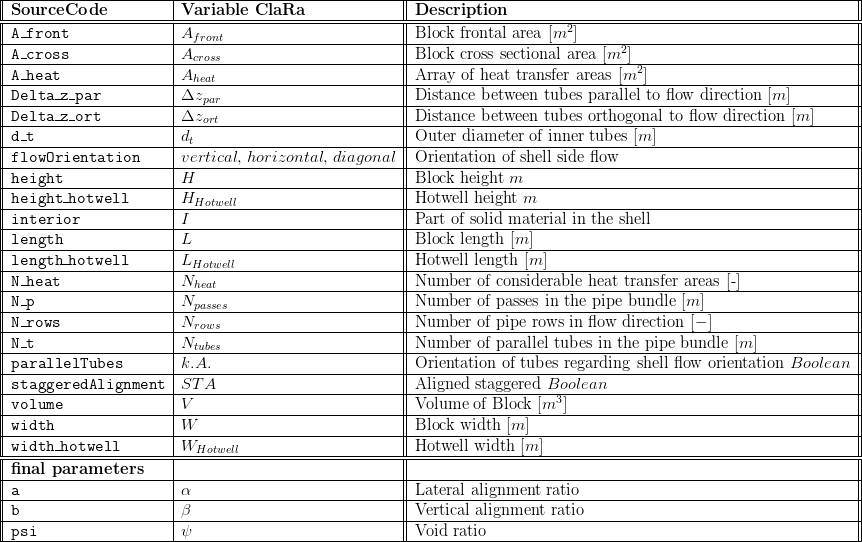

4. Nomenclature

5. Governing Equations

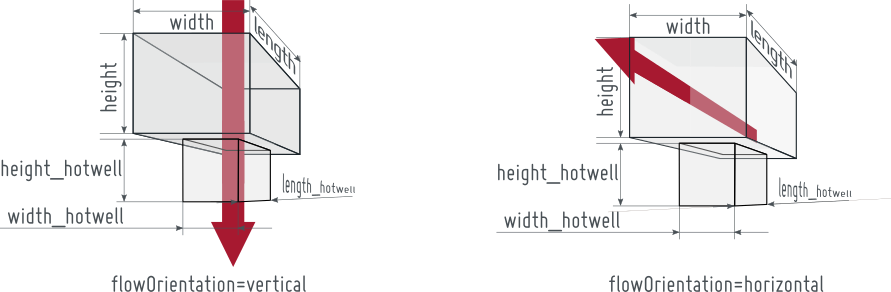

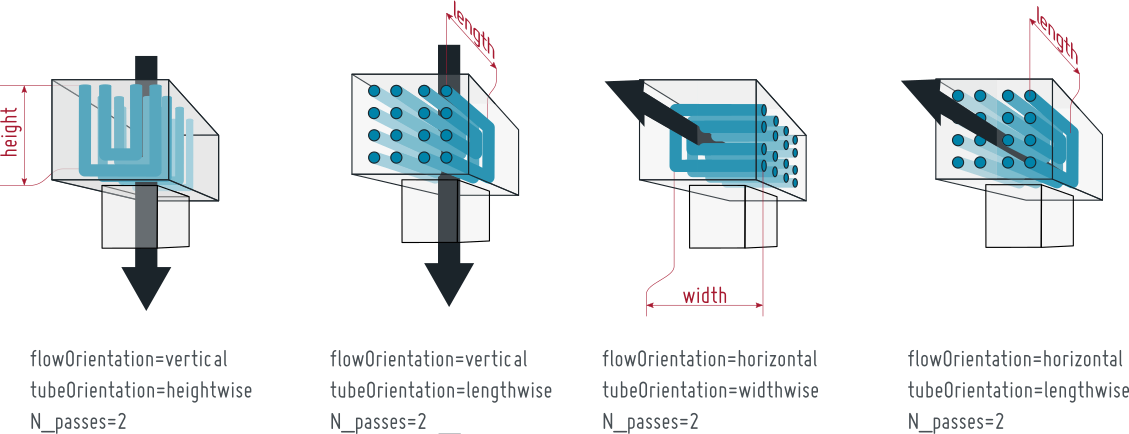

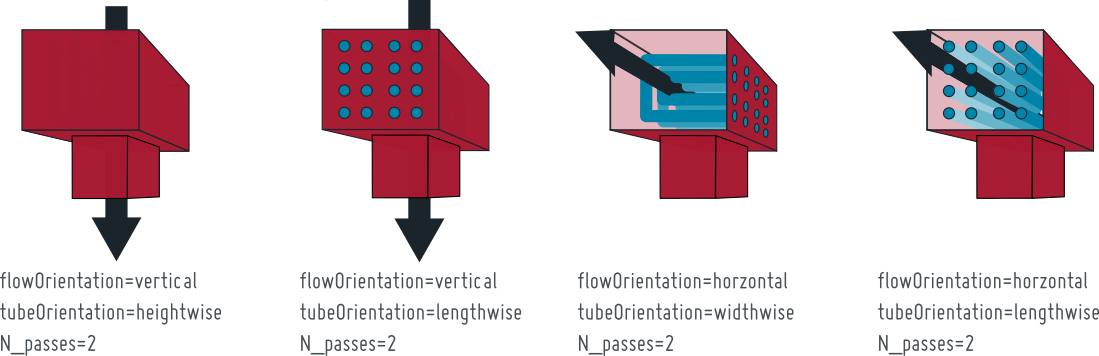

This model defines geometrical properties of a block shaped shell with a tube bank inside. The orientation of the block and the understanding of its main dimensions is always the same, as illustrated below. Furthermore, there is an orientation of the shell flow defined via flowOrientation. This parameter can be one of "vertical" and "horizontal".

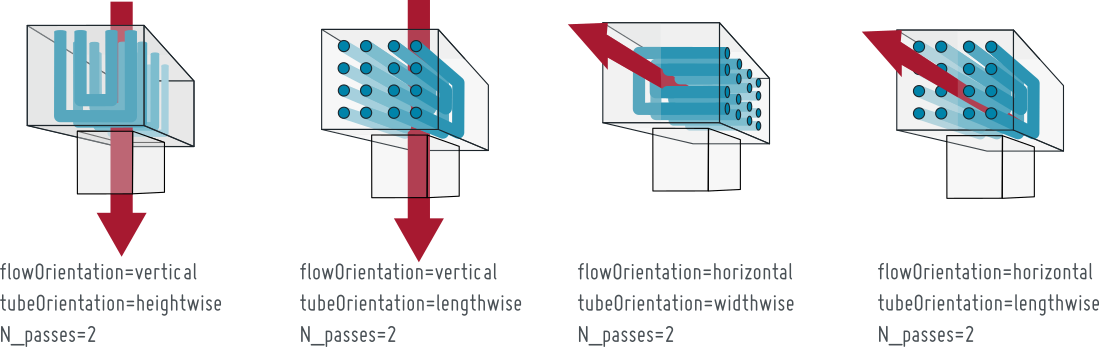

The orientation of the tube bank inside the block is defined with the parameter tubeOrientation. This is illustrated below:

5.2 Governing Model Equations

The HollowBlockWithTubesAndHotwell geometry is basically characterised by the block and hotwell dimensions (length, height, width), the shell side flow orientation and the tube bundle dimensions (diameter, length, Number of tubes and passes) with its relative orientation to the shell side flow direction .

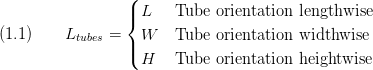

The tube length is defined with the parameter tubeOrientation.

The volume of the element is given by Eq.1 depending on the shell side flow direction and the relative orientation of the tubes,

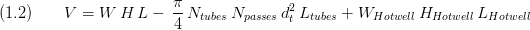

Also depending on the shell side flow direction the frontal area is determined by Eq.2.

The cross sectional area arises from Eq.3 according to the relative orientation of the tubes.

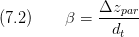

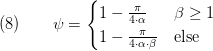

with  as void ration (see Eq. 8).

as void ration (see Eq. 8).

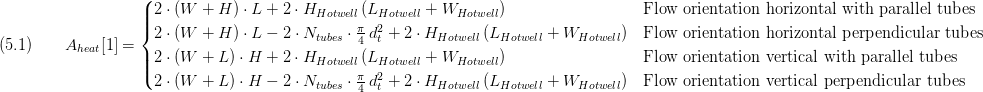

The nominal horizontal area is calculated via Eq. 4:

The entries of the vector of the heat transfer area  also has to be determined depending on the shell side flow orientation and the relative orientation of the tube bundle. For the HollowBlockWithTubesAndHotwell geometry the heat transfer area array is of the length

also has to be determined depending on the shell side flow orientation and the relative orientation of the tube bundle. For the HollowBlockWithTubesAndHotwell geometry the heat transfer area array is of the length  .

.

The first entry of  is the lateral surface of the block (see Eq. 5.1)

is the lateral surface of the block (see Eq. 5.1)

The second entry in the  array stands for the overall lateral surface of the internal tubes (see Eq.5.2)

array stands for the overall lateral surface of the internal tubes (see Eq.5.2)

The fillable height of the component is equivalent to the sum of the heights of the block and the hotwell

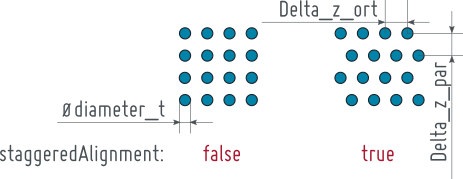

In case of perpendicular tube orientation the lateral and vertical alignment ratio are given by

and,

Finally the void ratio is determined via

6. Remarks for Usage

Whenever the tubes' volume exceeds the block's volume due to a high number of tubes or a large number of passes an assert will raise an error message. The same holds if the cross sectional area A_cross vanishes due to a too high interior. Additionally, z_in and z_out must be smaller than height_fill and greater equal than 0. Also a tube bundle parametrized too large for the volume will lead to an error message.

- A_cross > 0

- volume > 0

- z_in < height_fill

- z_out < height_fill

- z_in >= 0

- z_out >= 0

- Delta_l_par < 0

- Delta_l_ort < 0

- A_narrowed_par < 0

- A_narrowed_ort < 0

If one or more of the parameters Delta_l_par, Delta_l_ort, A_narrowed_par or A_narrowed_ort are below 0 the tube bundle is too large in one or multiple volume dimensions. Please check the tube spacing or the number of tube rows to reduce tube bundle size in the specified dimension or increase the height, width or length of the volume so that the tube bundle fits inside.

If the tube orientation is parallel to flow direction, please be aware that the parameters Delta_z_par and Delta_z_ort have no reasonable meaning geometrically but maybe have an impact in the heat transfer corellation for tube bundles.

7. Validation

8. References

9. Version History

20.02.2012 - v01 - Initial implementation - Friedrich Gottelt, XRG Simulation GmbH

08.02.2016 - v1.1.0 - bugfixed A_heat[1] (not used in current models)