VolumeVLE L3_TwoZonesNPort

Created Monday 22 October 2012

Basic two-zone model heat and mass storage as well as convective heat transfer and pressure differences due to friction and geostatic effects taking for each of the zones into account. Variable number of inlet and outlet ports.

1. Purpose of Model

The models is recommended when two distinct phases (vapour and liquid) are present and non-ideal phase interaction is expected. Both phases may be (independent from each other) subcooled, superheated or in the two-phase region. This is especially the case in condensing heat exchangers and pressurized storage tanks. The model is used as a basic model to form various components like:

- Compact heat exchangers e.g. condensers, preheaters

- Storage tanks, e.g. deaerators, steam drums

2. Level of Detail, Physical Effects Considered and Physical Insight

2.1 Level of Detail

Referring to Brunnemann et al. [1], this model refers to the level of detail L3 because the system is modelled with the use of balance equations for two distinct zones, namely the zone of liquid and vapour volume.

2.2 Physical Effects Considered

- Conservation of Mass

- Simplified conservation of momentum (no advection term, steady state)

- Conservation of Energy

- Reverse flow

- Heat Transport due to convection

- Pressure loss due to friction.

- non-ideal phase separation and mixing based on phenomenological model ideas

2.3 Level of Insight

Heat Transfer

- ControlVolumes:Fundamentals:HeatTransport:Generic HT:Constant L3

- ControlVolumes:Fundamentals:HeatTransport:VLE HT:Constant L3 ypsDependent

- ControlVolumes:Fundamentals:HeatTransport:Generic HT:IdealHeatTransfer L3

Pressure Loss

- ControlVolumes:Fundamentals:PressureLoss:Generic PL:LinearParallelZones L3

- ControlVolumes:Fundamentals:PressureLoss:Generic PL:NoFriction L3

- ControlVolumes:Fundamentals:PressureLoss:Generic PL:LinearSerialZones L3

Spacial Distribution

- ControlVolumes:Fundamentals:SpatialDistributionAspects:RealSeparated

- ControlVolumes:Fundamentals:SpatialDistributionAspects:RealMixed

3. Limits of Validity

- Averaging assumption within the zonal volumes violated.

- The equations imply that the outlet states are equal to the states in the balance equations - Not true for large volumes and high gradients.

4. Interfaces

4.1 Physical Connectors

Basics:Interfaces:FluidPortIn inlet[geo.N_inlet] - an arbitrary number of inlet ports

Basics:Interfaces:FluidPortOut outlet[geo.N_inlet] - an arbitrary number of outlet ports

Basics:Interfaces:HeatPort a heat

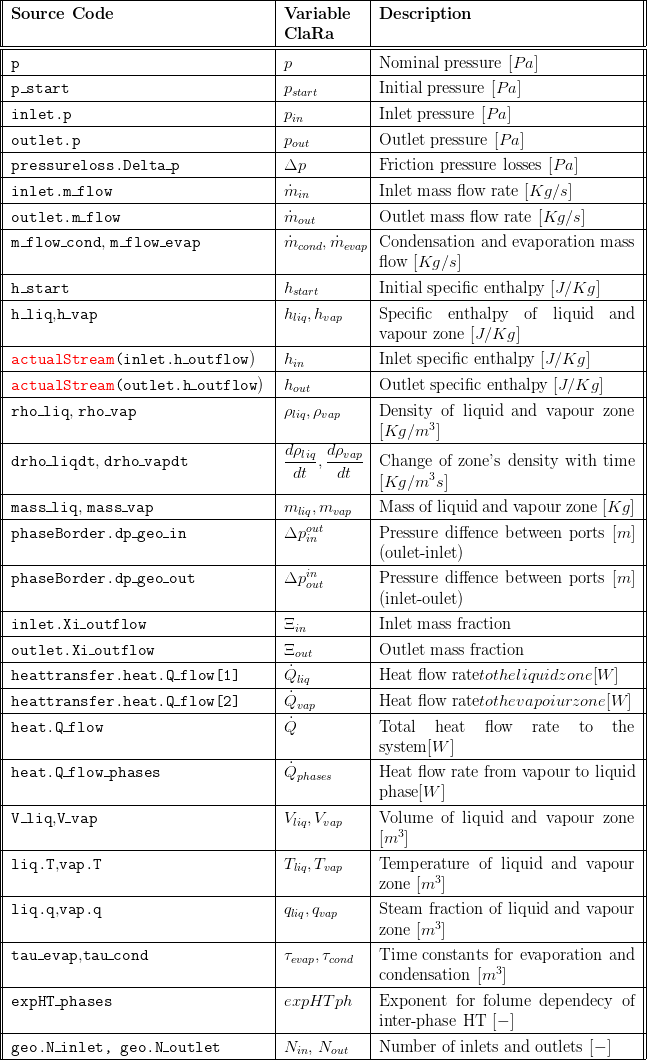

5. Nomenclature

6. Governing Equations

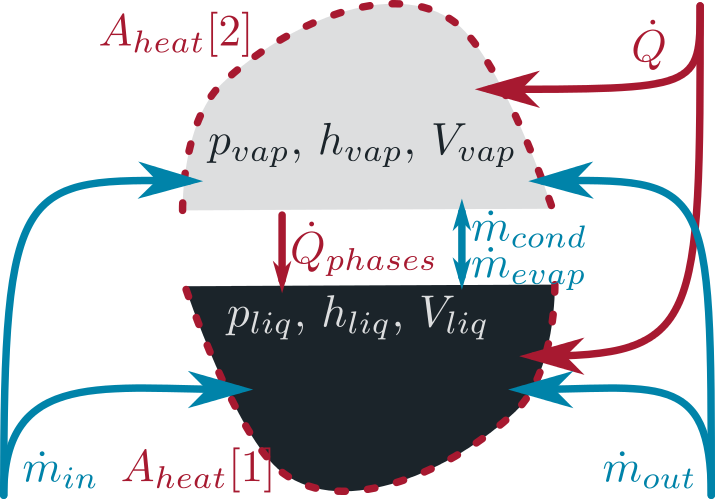

6.1 System Description and General model approach

The general model structure is defined as illustrated below: Two distinct volumes are considered referring to the liquid and vapour volume in the system. The two volumes can exchange mass and heat between each other. Furthermore, heat can be transferred with the surrounding which is handled using replaceable models, see section 2.3 Heat Transfer. Pressure losses are also addressed with replaceable models, see section 2.3 Pressure Loss. The allocation of the entering and outgoing enthalpy flows takes phenomenological approaches for separating and mixing into account, see section 2.3 Spacial Distribution. The location of the zonal pressure can either be either equal (at the liquid/vapour surface) or different (vapour pressure at the surface while the liquid pressure is at the liquid zone's half filling level), see subsection 6.2 Location of Pressure States.

6.2 Governing Model Equations

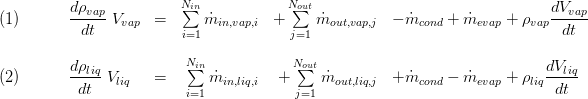

Conservation of Mass

The mass balance for each of the zones considers evaporation and condensation mass flow rates, volume changes and mass flows through the inlet and outlet connectors. These mass flows are allocated to the vapour and liquid zone according to the replaceable model PhaseSeparation, see section 2.3 Spatial Distribution. The balance equations read:

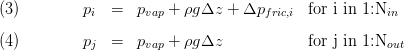

Conservation of Momentum

The momentum balances applied for each of the ports allow the calculation of pressure distribution at the model boundaries. Two major simplifications are applied:

- steady state

- neglect of momentum flows through the ports

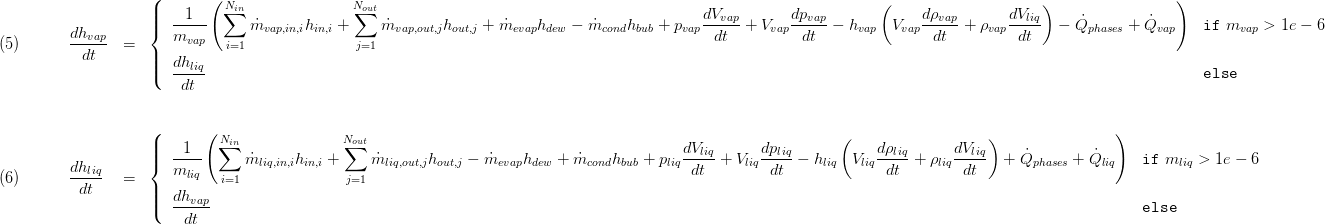

Conservation of Energy

The energy balances for both zones consider entering and leaving enthalpy flow rates as well as energy transport between the zones due to heat and mass transfer. The mass flows entering and leaving are allocated to the vapour and liquid zone according to the replaceable model PhaseSeparation, see section 2.3 Spatial Distribution. Please note, there are three terms in the equations below that take the derivatives of volume, density and pressure into account. These terms are derived from the total derivative of the inner energy of the zone and appear here due to the special choice of state variables as discussed in Basic Concepts of Modelling.

In the equations above two cases are distinguished to handle vanishing zones, i.e. if we have only liquid or only vapour in our component. In these cases the enthalpy of vanishing zone follows the other remaining zone's enthalpy. This concept allows to simulate completely filled or void tanks which is an important case for certain components like start-up bottles and cyclone separators. The heat flow rates to the surrounding are determined by applying a replaceable heat transfer model, see section 2.3 Heat Transfer.

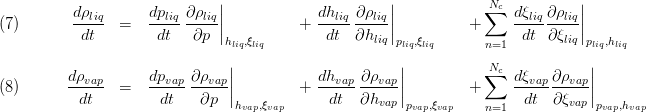

The model's density is taken as an explicit function of the states, its total derivative should be used for completeness of the model given by:

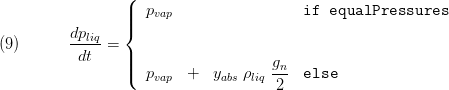

Location of Pressure States

The liquid and vapour state are defined by the pressure and enthalpy at the respective zones. While the spec. enthalpy and the density of the zones is defined by the energy and mass balance equations for each of the zones the pressure of the zones are connected to each other via algebraic equations defining the relative position of the two states. Depending on the parameter equalPressures the liquid and vapour zone pressure can be either equal or not:

See remarks for initalisation with equalPressures=false.

Chemistry

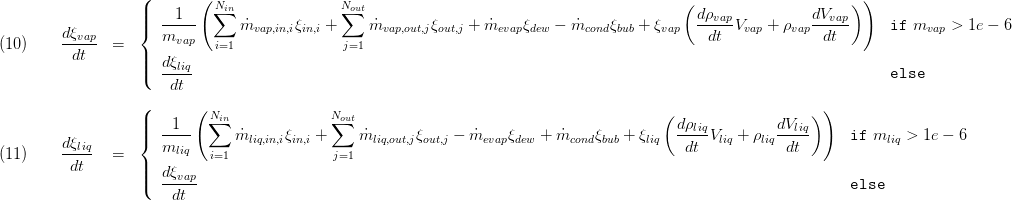

No chemical reactions are considered leading to the following  species mass balances for the two zones. Note that these equations are only valid (and evaluated) when a mixture of fluids is used i.e. the number of species

species mass balances for the two zones. Note that these equations are only valid (and evaluated) when a mixture of fluids is used i.e. the number of species  .

.

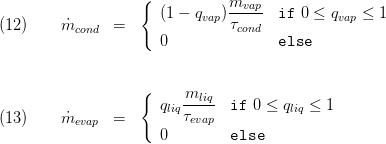

Mass Transfer between the Zones

The evaporation and condensation mass flow rates are determined according to the vapour mass fraction in the liquid zone and the liquid fraction in the vapour zone introducing two time constants for evaporation and condensation, respectively. These can be tuned by the user and affect strongly the behaviour of the model. See [2] for a discussion of these parameters.

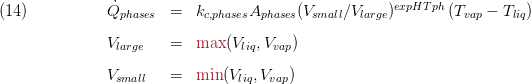

Heat Transfer between the Zones

The model for the inter-phase heat transfer assumes constant values for heat phase surface and heat transfer coefficient:

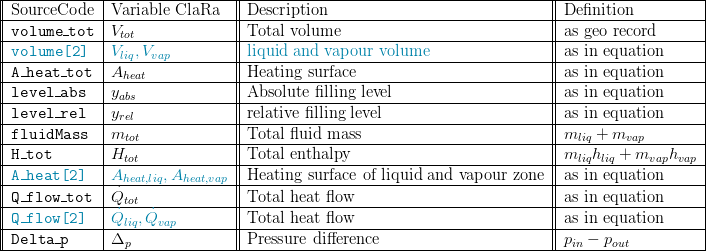

Summary

A summary is available including the following:

- an outline record:

- Basics:Records:FlangeVLE inlet[N_inlet], outlet[N_outlet]

- Basics:Records:FluidVLE L34 fluid

7. Remarks for Usage

- This model is applied in a number of component models either via instantiation of inheritance, see

- The model shall preferred over VolumeVLE L3 TwoZones whenever a number of inlet and outlet flows are present as it will be more robust w.r.t. numerical stability and fluctuations between parallel paths, e.g. in different evaporation heating surfaces connected to a steam drum.

- When the model is applied with a phase separating characteristic, e.g. by applying ControlVolumes:Fundamentals:SpatialDistributionAspects:RealSeparated it is advisable to put the vertical locations of the inlet and outlet connectors not exactly to the top and bottom but to keep some space left. This will improve the numerical stability in case of a completely empty or completely full vessel.

- If equalPressures=false it is recommended to use the initOption 211. Thus, it is ensured that the vapour pressure is initialised with the pressure p_start. Otherwise, negative initial pressures could occur, if the geodetic pressure difference is larger than the absolute pressure, e.g. in condensers.

9. References

[1] Johannes Brunnemann and Friedrich Gottelt, Kai Wellner, Ala Renz, André Thüring, Volker Röder, Christoph Hasenbein, Christian Schulze, Gerhard Schmitz, Jörg Eiden: "Status of ClaRaCCS: Modelling and Simulation of Coal-Fired Power Plants with CO2 capture", 9th Modelica Conference, Munich, Germany, 2012

[2] Sebastian Meinke and Friedrich Gottelt, Martin Müller, Egon Hassel: "Modelling of Coal-Fired Power Units with ThermoPower Focussing on Start-Up Process", 8th Modelica Conference, Dresden, Germany, 2011

10. Authorship and Copyright Statement for original (initial) Contribution

Author:

DYNCAP/DYNSTART development team, Copyright 2011 - 2022.

Remarks:

This component was developed during DYNCAP/DYNSTART projects.

Acknowledgements:

ClaRa originated from the collaborative research projects DYNCAP and DYNSTART. Both research projects were supported by the German Federal Ministry for Economic Affairs and Energy (FKZ 03ET2009 and FKZ 03ET7060).

CLA:

The author(s) have agreed to ClaRa CLA, version 1.0. See https://claralib.com/pdf/CLA.pdf

By agreeing to ClaRa CLA, version 1.0 the author has granted the ClaRa development team a permanent right to use and modify his initial contribution as well as to publish it or its modified versions under the 3-clause BSD License.

11. Version History

Date - Version - Description of changes - author/revisor

- 25.06.2013 - v0.1 - initial implementation of the model - Friedrich Gottelt, XRG Simulation

- 30.04.2016 - v1.1.1 - improved numerical robustness (handling of two phase inlet flows and allowance of different pressures in the zones) - F. Gottelt, T. Hoppe, XRG SImulation GmbH

- 05.09.2016 - v1.2 - improved numerical robustness if expert setting equalParameters==false is chosen - F. Gottelt, T. Hoppe, XRG Simulation GmbH

- 24.04.2017 - v1.2.2 - added noEvent in several equations containing actualStream

Backlinks: ClaRa:Components:HeatExchangers:HEXvle2vle L3 2ph BU ntu ClaRa:Components:HeatExchangers:HEXvle2vle L3 2ph BU simple ClaRa:Components:HeatExchangers:HEXvle2vle L3 2ph CH ntu ClaRa:Components:HeatExchangers:HEXvle2vle L3 2ph CH simple ClaRa:Components:HeatExchangers:HEXvle2vle L3 2ph CU ntu ClaRa:Components:HeatExchangers:HEXvle2vle L3 2ph CU simple ClaRa:Components:MechanicalSeparation:Bottle L3 ClaRa:Components:MechanicalSeparation:Drum L3 ClaRa:Components:MechanicalSeparation:FeedWaterTank L3 ClaRa:Components:MechanicalSeparation:SteamSeparatorVLE L3 ClaRa:Basics:ControlVolumes:FluidVolumes:VolumeVLE L3 TwoZones ClaRa:Components:VolumesValvesFittings:Fittings:JoinVLE L3 Y