SplitVLE L2 Y

Created Freitag 20 November 2015

Adiabatic VLE-fluid split model describing an ideally stirred fluid volume with dynamic energy and mass balance including pressure losses at each port.

1. Purpose of Model

The model is used as separating component with a constant volume for two inlets.

2. Level of Detail, Physical Effects Considered and Physical Insight

2.1 Level of Detail

Referring to Brunnemann et al. [1], this model refers to the level of detail L2.

2.2 Physical Effects Considered

- Conservation of Mass

- Conservation of Energy

- Reverse flow

- Pressure losses

2.3 Level of Insight

Pressure Loss

Inlet

- NoFriction : friction free flow between inlet and outlet Fundamentals:NoFriction

- LinearPressureLoss : Linear pressure loss based on nominal values Fundamentals:Linear

Outlet 1

- NoFriction : friction free flow between inlet and outlet Fundamentals:NoFriction

- LinearPressureLoss : Linear pressure loss based on nominal values Fundamentals:Linear

Outlet 2

- NoFriction : friction free flow between inlet and outlet Fundamentals:NoFriction

- LinearPressureLoss : Linear pressure loss based on nominal values Fundamentals:Linear

3. Limits of Validity

- Ideal mixing assumptions are not valid

- The equations imply that the outlet states equal the states in the balance equations - Not true for large volumes and high gradients.

- Heat losses/input

4. Interfaces

4.1 Physical Connectors

- inlet, outlet1 and outlet2 connectors combined for:

- Mass flow rate in the connection ports [kg/s].

- Thermodynamic pressure in the connection ports [Pa].

- Specific thermodynamic enthalpy close to the connection port s [J/kg].

- Medium properties at the ports.

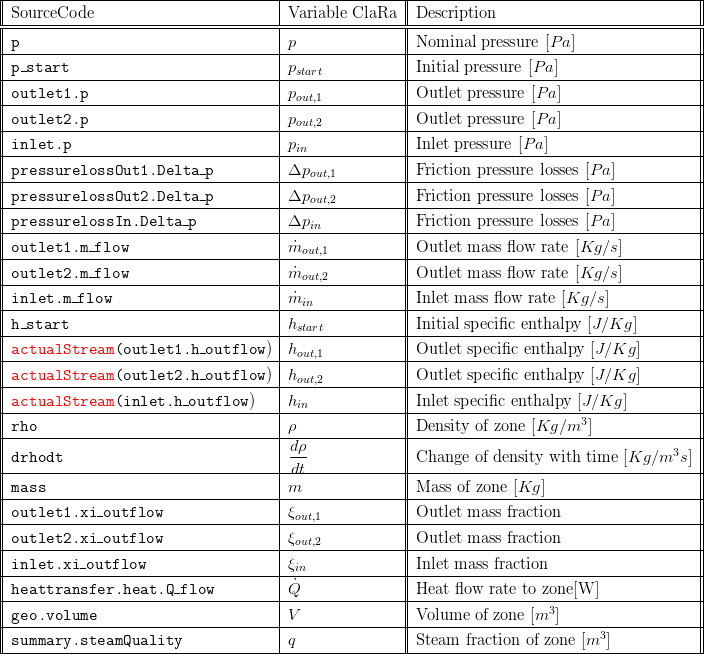

5. Nomenclature

6. Governing Equations

6.1 System Description and General model approach

The model describes an ideally stirred volume element with two outlets and one inlet port.

6.2 Governing Model Equations

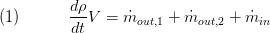

Conservation of Mass

The mass balance for the constant volume considers mass flows through the inlet and outlet connectors. The balance equation reads:

Conservation of Momentum

We use balance of stationary momentum to model the frictional pressure losses in the join.

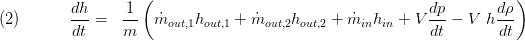

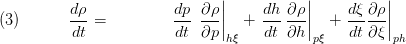

Conservation of Energy

The energy balance for the control volume considers incoming and outgoing enthalpy flow rates. Please note, there are two terms in the equations below that take the derivatives of density and pressure into account. These terms are derived from the total derivative of the inner energy of the zone and appear here due to the special choice of state variables as discussed in Basic Concepts of Modelling. The term with the density derivative can be deactivated with setting the parameter preciseTwoPhase in the expert setting dialog to false. Thus, the influence of h is removed from the right hand side of the equation.

The model's density is taken as an explicit function of the states its total derivative should be used for completeness of the model given by:

Chemistry

no chemistry is considered:

Summary

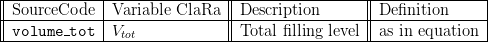

A summary is available including the following:

- an outline record:

- Basics:Records:FlangeVLE outlet1,outlet2, inlet

- Basics:Records:FluidVLE L2 fluid

7. Remarks for Usage

- The term with the density derivative can be deactivated with setting the parameter preciseTwoPhase in the expert setting dialog to false. Thus, the influence of h is removed from the right hand side of the equation.

- In many cases positioning of pressure losses at the ports is crucial for the overall simulation performance. In some cases so-called DAE-index reduction problems are caused by inappropriate pressure loss positioning.To help the user with this issue the connections featuring a pressure loss between the respective port and the next pressure state are marked blue, see figure below. Each of the port's pressure loss can be set individually.

8. Validation

9. References

[1] Johannes Brunnemann and Friedrich Gottelt, Kai Wellner, Ala Renz, André Thüring, Volker Röder, Christoph Hasenbein, Christian Schulze, Gerhard Schmitz, Jörg Eiden: "Status of ClaRaCCS: Modelling and Simulation of Coal-Fired Power Plants with CO2 capture", 9th Modelica Conference, Munich, Germany, 2012

10. Authorship and Copyright Statement for original (initial) Contribution

Author:

DYNCAP/DYNSTART development team, Copyright 2011 - 2022.

Remarks:

This component was developed during DYNCAP/DYNSTART projects.

Acknowledgements:

ClaRa originated from the collaborative research projects DYNCAP and DYNSTART. Both research projects were supported by the German Federal Ministry for Economic Affairs and Energy (FKZ 03ET2009 and FKZ 03ET7060).

CLA:

The author(s) have agreed to ClaRa CLA, version 1.0. See https://claralib.com/pdf/CLA.pdf

By agreeing to ClaRa CLA, version 1.0 the author has granted the ClaRa development team a permanent right to use and modify his initial contribution as well as to publish it or its modified versions under the 3-clause BSD License.

11. Version History

- 03.03.2013 - v.0.1 - initial implementation - Friedrich Gottelt, XRG Simulation

- 24.04.2017 - v1.2.2 - added noEvent to actualStream operator - Timm Hoppe, XRG Simulation

- 26.06.2018 - v1.3.1 - added visualisers for inlet and outlet friction - Friedrich Gottelt, XRG Simulation