SteamSeparatorVLE L1

Created Freitag 12 Februar 2016

A simple model of a steam separator like a steam cyclone or a start-up vessel.

1. Purpose of Model

This model is suitable for small-sized steam separators like cyclones and for cases where the mass storage capacities of the components are not of relevance.

2. Level of Detail, Physical Effects Considered and Physical Insight

2.1 Level of Detail

Referring to Brunnemann et al. [1], this model refers to the level of detail L1 because the system is modelled with steady balance equations and simple, effective characteristics.

2.2 Physical Effects Considered

- steam separation

- constant efficiency for separating steam from the liquid leaving at outlet2 and for separating liquid from the steam at outlet1.

2.3 Level of Insight

None of the physical effects considered is available at different levels of insight.

3. Limits of Validity

- reverse flow is not supported!

- energy and mass storage is not supported

- separation processes are based on density differences. Thus, with increasing pressures the efficiency decreases. This is not considered in the model which leads to an decreasing steam quality at the liquid outlet (outlet2) at increasing pressures.

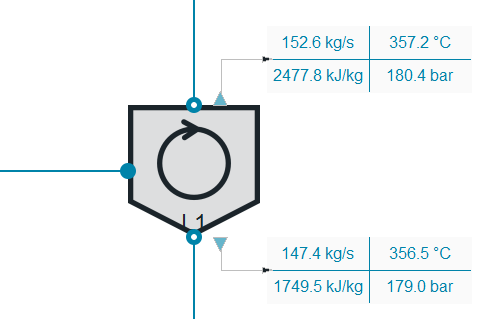

4. Interfaces

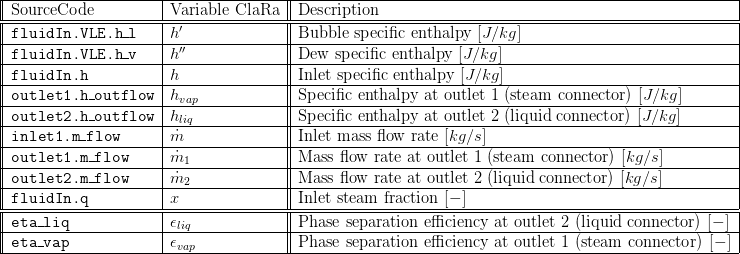

5. Nomenclature

6. Governing Equations

6.1 System Description and General Modelling Approach

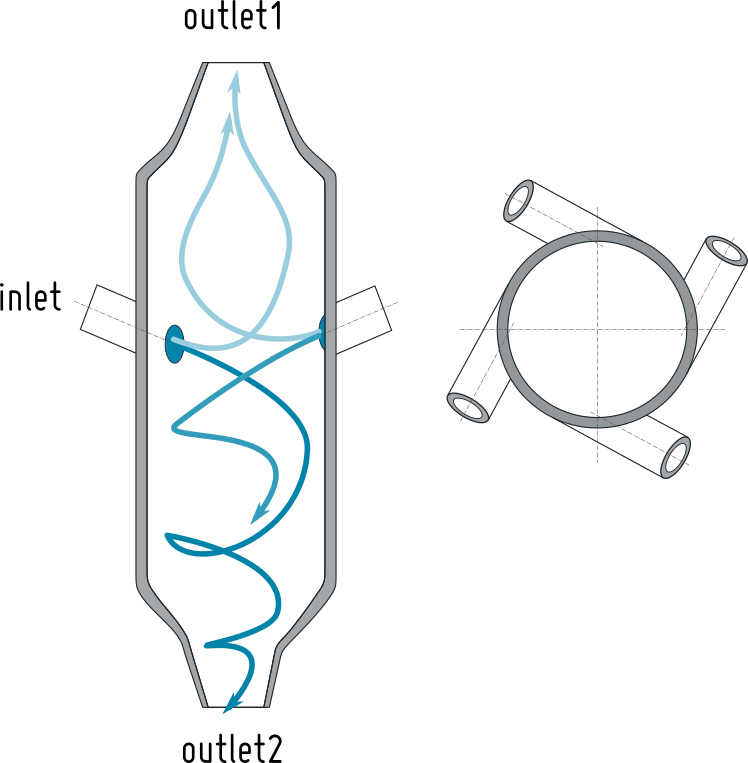

The incoming mass flow rate is separated according to its steam quality, i.e. the steam fraction of the inlet mass flow will leave the component via the steam connector (outlet1). In addition to this ideal separation behaviour a separating efficiency is considered for both the steam and liquid connectors. This results in wet steam conditions at both connectors. This idea is illustrated below.

6.2 General Model Equations

Energy Conservation

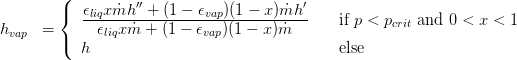

A steady state formulation for the energy balance is applied according to above considerations to derive the specific enthalpy at the outlet ports.Whenever the input sees single phase fluid the corresponding single phase spec. enthalpy is passed to both outlet ports.

Please be aware that in case of reverse flow no valid enthalpy is calculated resulting in temporarily inaccurate values. Depending on the use-case this may lead to divergent systems.

Mass Conservation

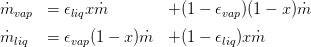

Again, a steady state formulation is used to ensure mass conservation in the systems:

7. Remarks for Usage

- According to [2] the steam quality at outlet1 is expected to be 0.96 at 60 bar and decreasing to 0.90 at 180 bar. Steam quality at the liquid outlet2 are expected to be approximately 0.01 and 0.06 at 60 bar and 180 bar, respectively. This behaviour that reflects decreasing density differences of water and steam at higher pressures is not considered in this model.

- Efficiency parameter > 0.999 are not allowed.

8. Validation

9. References

[1] Johannes Brunnemann and Friedrich Gottelt, Kai Wellner, Ala Renz, André Thüring, Volker Röder, Christoph Hasenbein, Christian Schulze, Gerhard Schmitz, Jörg Eiden: "Status of ClaRaCCS: Modelling and Simulation of Coal-Fired Power Plants with CO2 capture", 9th Modelica Conference, Munich, Germany, 2012

[2] Karl Strauß: "Power Plant Technology for Exploitation of Fossil, Nuclear and Regenerative Energy" (in German), Springer, 6th edition, 2009.

10. Authorship and Copyright Statement for original (initial) Contribution

Author:

DYNCAP/DYNSTART development team, Copyright 2011 - 2022.

Remarks:

This component was developed during DYNCAP/DYNSTART projects.

Acknowledgements:

ClaRa originated from the collaborative research projects DYNCAP and DYNSTART. Both research projects were supported by the German Federal Ministry for Economic Affairs and Energy (FKZ 03ET2009 and FKZ 03ET7060).

CLA:

The author(s) have agreed to ClaRa CLA, version 1.0. See https://claralib.com/pdf/CLA.pdf

By agreeing to ClaRa CLA, version 1.0 the author has granted the ClaRa development team a permanent right to use and modify his initial contribution as well as to publish it or its modified versions under the 3-clause BSD License.

11. Version History

- 07.03.2016 - 1.1.0 - Initial Implementation - Friedrich Gottelt/XRG Simulation GmbH

- 26.03.2019 - 1.4.0 - Corrected placement of eye connectors - Timm Hoppe, XRG Simulation GmbH

Backlinks: ClaRa:Components:MechanicalSeparation:Bottle L3